Intech Can Making Machinery - iCamFollowers® eliminate cam wear, lubrication and help increase speed in Belvac neckers

Cam and cam follower wear on Belvac neckers has always been an issue. The high frequency of repeated metal on metal impact, generated by extrusion forces, spindle weight and associated acceleration force cause a deterioration of the surfaces which leads to wear.

Other wear accelerating factors include skidding of the cam follower on the cam caused by over-greasing, heavy spring load used on high speed neckers such as the Super K and up and down sliding of the cam followers [lift] when the spindle is worn out. While the cam usually has a heavy dose of grease on the surface, the lubrication can only go so far to prevent wear.

Containing the cam and cam follower wear becomes more important with increasing line speeds, as the traditional metal components cause disproportionate rise in maintenance and downtime costs.

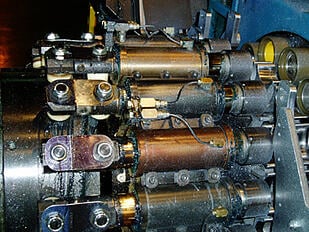

Several years ago, Intech introduced self-lubricating Intech iCamFollowers® for the Belvac neckers which eliminate both the cam wear and the need for lubrication. Intech iCamFollowers® are constructed with two precision ball bearings lubricated for life and a precision machined Power-Core™ plastic tire. They present a very low rolling resistance, exhibit long wear life, absorb shock during impact on the cam, are 35% lighter compared to metal cam followers and do not wear the cam surface.

Since their market introduction two years ago, a number of Intech’s customers converted entire necker lines and installed the Intech cam followers on Belvac spindles. By doing so, they were able to disconnect the central lubrication lines to the cam followers, leaving only the spindle lubrication lines operational. (See images 1 through 4 below). On lines equipped with Intech’s patented square rams (spindles), all lubrication lines were disconnected, leaving the turret clear of grease.

Images 1-4) Intech iCamFollowers® installed on a Belvac full contact ram on the 795 necker

Intech iCamFollowers® are being used on all Belvac necker types: 595, 795 and Super K. With installed Intech cam followers several of the 595 lines are now running at 2800cpm, approaching the design speeds of the Super K lines.

High speed neckers require a constant grease supply to the cam follower which can lead to over greasing. Heavily greased metal cam followers can skid and slide, contributing to rapid wear. To keep the metal cam follower rolling at all times, the spindle manufacturer introduced a “full contact” design in the 795 and Super K neckers, using a heavy spring to preload the cam followers on the cam. The combination of high speed and spring pressure prove to disproportionately increase downtime to change worn cam follower, and often preventing the necker to reach its design speed of 3000cpm and adding to production costs.

In contrast, the spring load does not increase the wear on Intech cam followers as the material is elastic enough to absorb both the spring load and the extrusion force without permanent deformation. Customers report that the Intech cam followers are holding up well on the 795 and Super K neckers.

Many of the spring loaded spindles were replaced with the patented Intech square rams [see image 5 above], which do not employ the spring, a design similar to the 595 spindle. [This ram design, can be used across all Belvac neckers, significantly reducing manufacturing costs and the cost to the customer]. Having proven that the Intech cam followers will run at high speeds without the full contact feature, we can now safely convert any 595 necker to a high speed machine by simply converting to Intech cam followers. This opens the way to increase the speed of 595 neckers to e.g. 2800 cpm, [and higher with Intech square rams], by simply installing Intech cam followers. There is no need for through hardened cams. (Practical tip: thin lubrication film on the cam will help to extend the cam followers’ life).

Can manufacturers still using metal cam followers, that experience high cam or cam follower wear, or are trying to increase the line speed, may benefit by trying Intech iCamFollowers®. The cost to convert to Intech cam followers is low, the benefits, on the other hand, huge.

|

Contact us on Freephone 1-877-218-2650 to request a no-obligation price quote for your necker line or send any questions via E-Mail to: info@intechpower.com |