Effects of Moisture Absorption

Nylons absorb moisture in equilibrium with the relative humidity of their immediate surroundings. Figure 1 compares the equilibrium moisture content for several grades of nylon. Intech Power-Core™ PA12GC (Gravity Cast), when fully submerged in water, absorbs a maximum of 1.4% while nylon 6 has an absoption rate of over 10%.

The effects of moisture absorption--dimensional change, and changes in physical properties--are negligible compared to those in other nylons.

Figure 1.

![CropperCapture[2]](http://cdn2.hubspot.net/hub/62516/file-14939738-jpg/images/croppercapture[2].jpg)

Dimensional Change

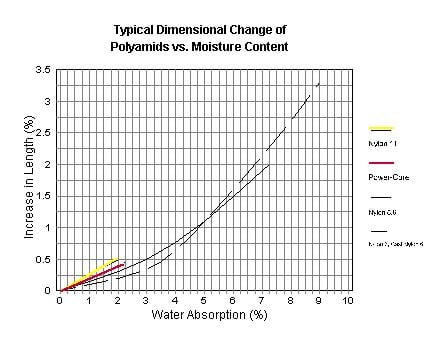

Figure 2 illustrates typical rates of dimensional change in polyamids caused by moisture absorption. PowerCore, with a maximum absorption of 1.4%, has a corresponding dimensional change of 0.2%. PA6 and PA6.6 absorb 9% and 7% of moisture respectively, resulting in a measurable dimensional change of 2% and 3.5%.

Figure 2.

Physical Properties

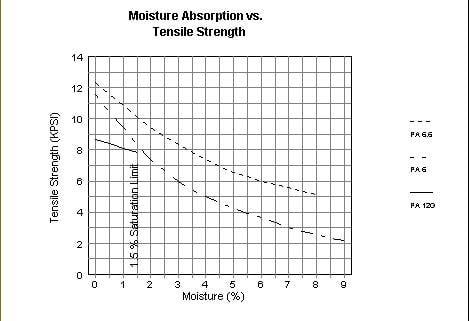

Figure 3 demonstrates PowerCore's superior tensile strength characteristics. Since PowerCore's moisture absorption is max. 1.4 %, the drop in tensile strength is very small. Conversely, the tensile strength of nylon 6 and 6.6 drops significantly with increasing moisture content. In the case of nylon 6, the drop in tensile strength from dry (100 %) to the saturated state is over 80 %. For nylon 6.6, the drop is over 60 %. With increased moisture content, modulus of elasticity and other stiffness properties are also reduced.