250 Herbert Avenue

Closter, New Jersey 07624 U.S.A.

1-877-218-2650

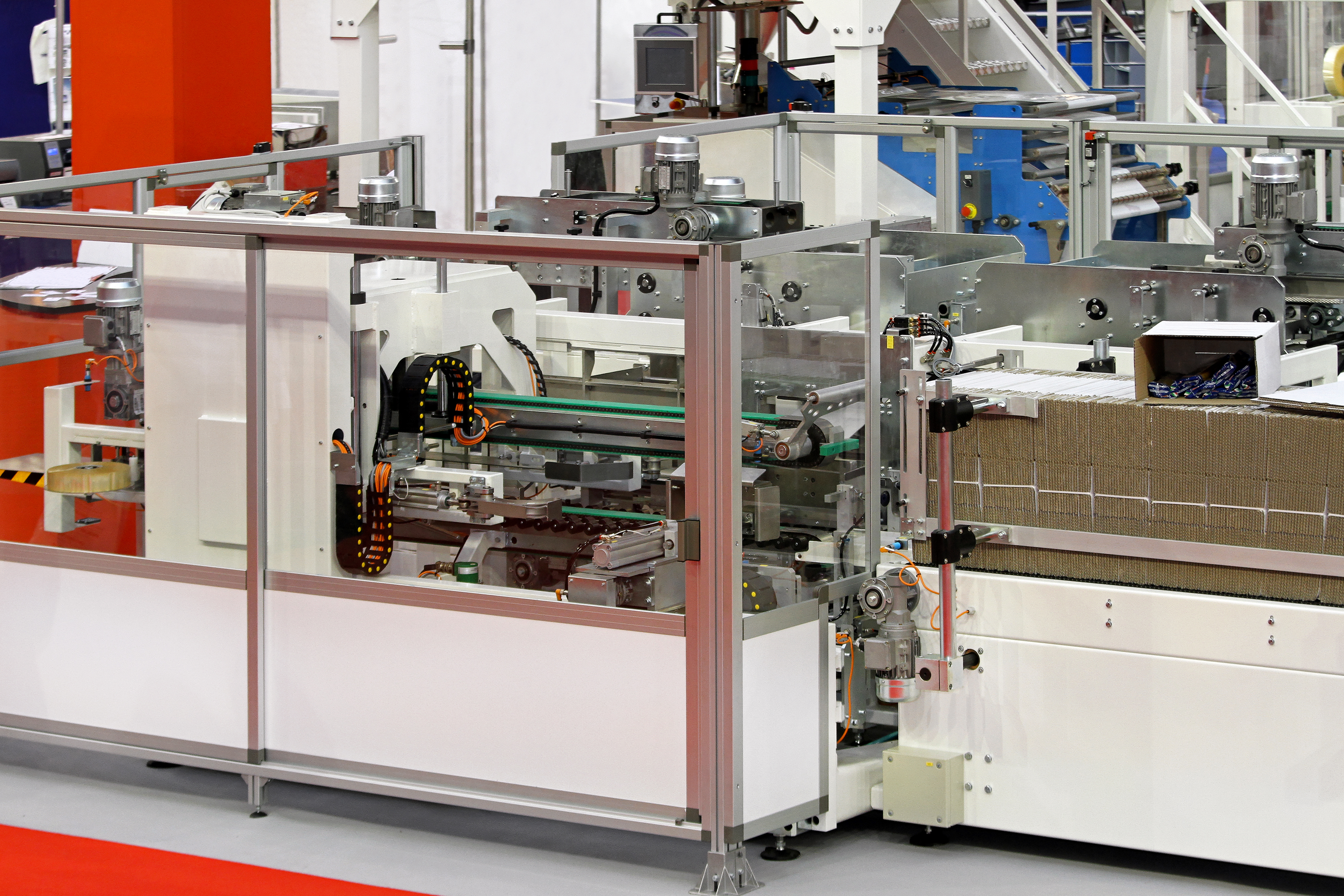

Put iNTECH’s PowerCore™ components to work in your plant and watch as your continued uptime, extended maintenance cycles and uninterrupted production generate ROI multiple times over.

There’s a reason why metal components come cheap. When factoring in their maintenance costs — even when they’re properly lubricated — and the loss in production when they fail, plants wind up paying dearly for parts advertised with a lower price tag. iNTECH’s PowerCore parts outlast and outperform metal components, even under load, saving money in the long run.

You don’t buy a part; you buy the part’s lifecycle. Using iNTECH’s PowerCore material in plant components lowers your maintenance requirements across the board:

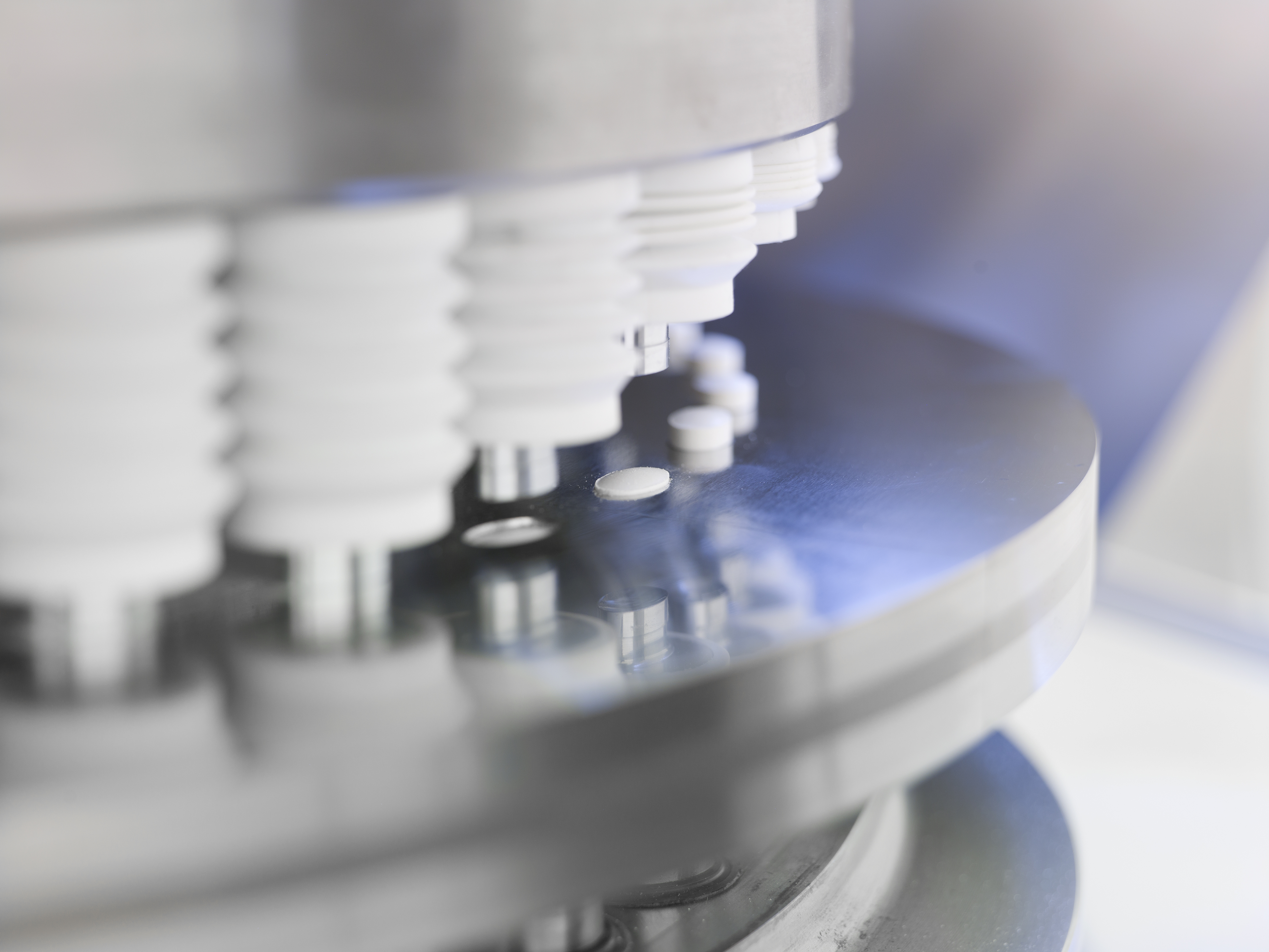

Our advanced polymer components reduce the risk of product contamination, all while enabling greater production volumes for longer. Consider the results we delivered when installing our PowerCore components on a customer’s can-making machines:

Metal and mold-injected plastic components may be attractive when first developing your plant’s machinery, but their quicker failure rate rapidly drive up costs through: