250 Herbert Avenue

Closter, New Jersey 07624 U.S.A.

1-877-218-2650

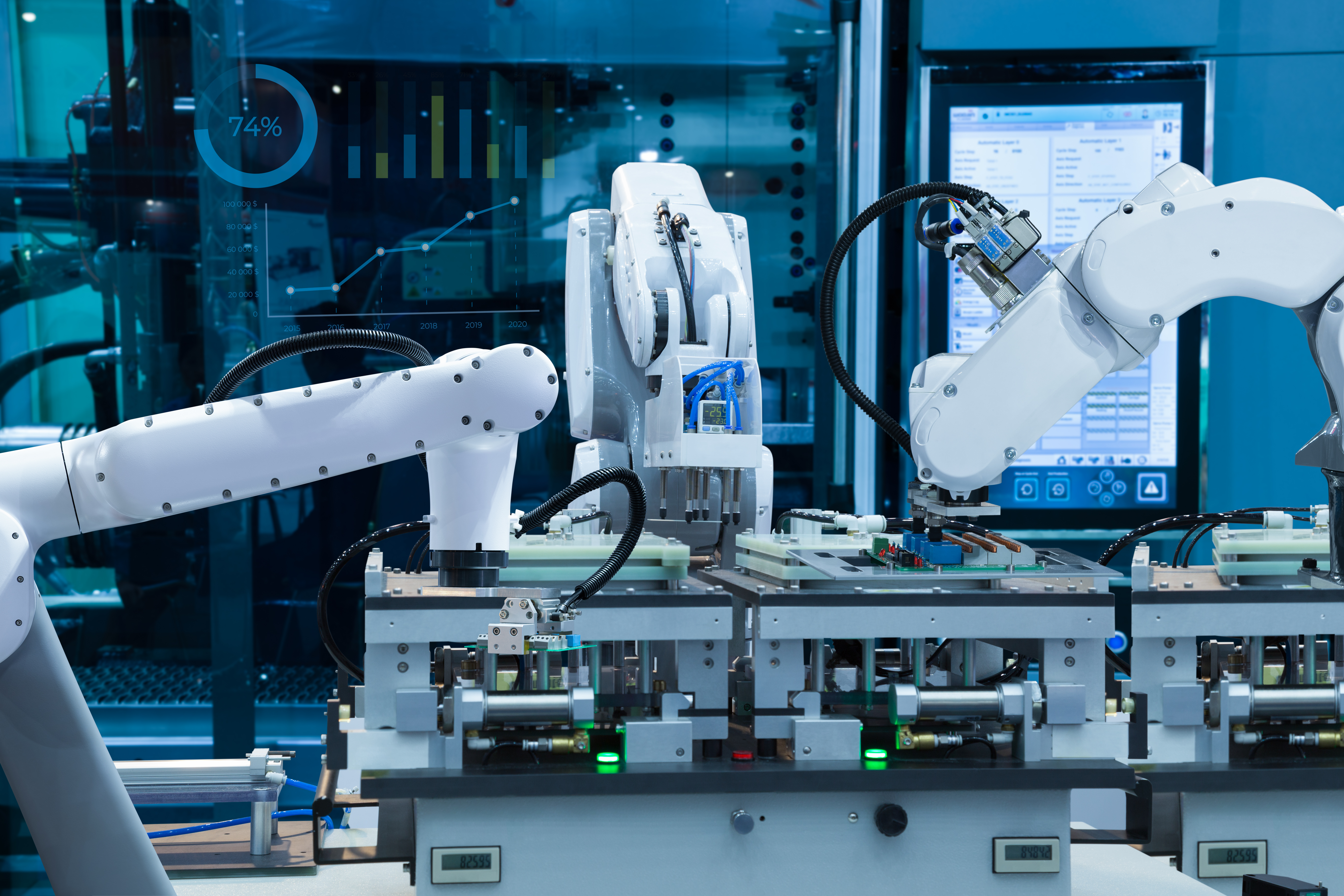

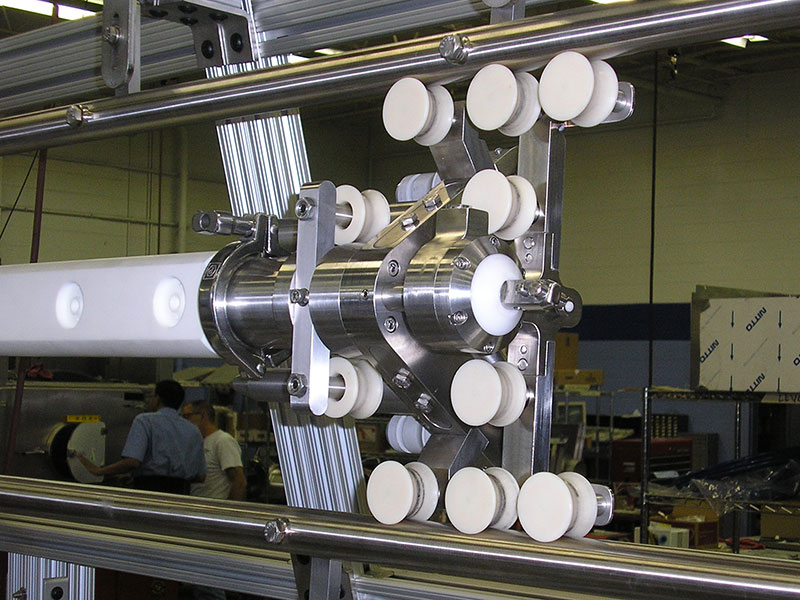

PowerCore composite motion components resist wear, run smoothly and eliminate the need for lubrication compared to their all-metal counterparts.

The primary role of these components is to transmit motion, it’s important to pay attention to the materials that make up the roller’s bearing surface. Selecting a hybrid design, consisting of a composite load bearing surface over a metal roller bearing, offers some compelling technical advantages. This design also contributes to the reliable, fast motion machine builders expect.

Track rollers and cam followers made from our proprietary PowerCore composite facilitate high-speed, energy-efficient motion in several ways:

Unlike metals, our PowerCore polymer dampens shock and vibration. In motion systems requiring cam followers, the polymer absorbs the damaging shock and vibration caused by reciprocating motion, unlocking several benefits:

The true cost of cam followers and track rollers has very little to do with their purchase price and everything to do with their lifecycle cost. Our PowerCore track rollers, cam followers and other power transmission components have extremely high ROI and save over the long haul in the following ways: