250 Herbert Avenue

Closter, New Jersey 07624 U.S.A.

1-877-218-2650

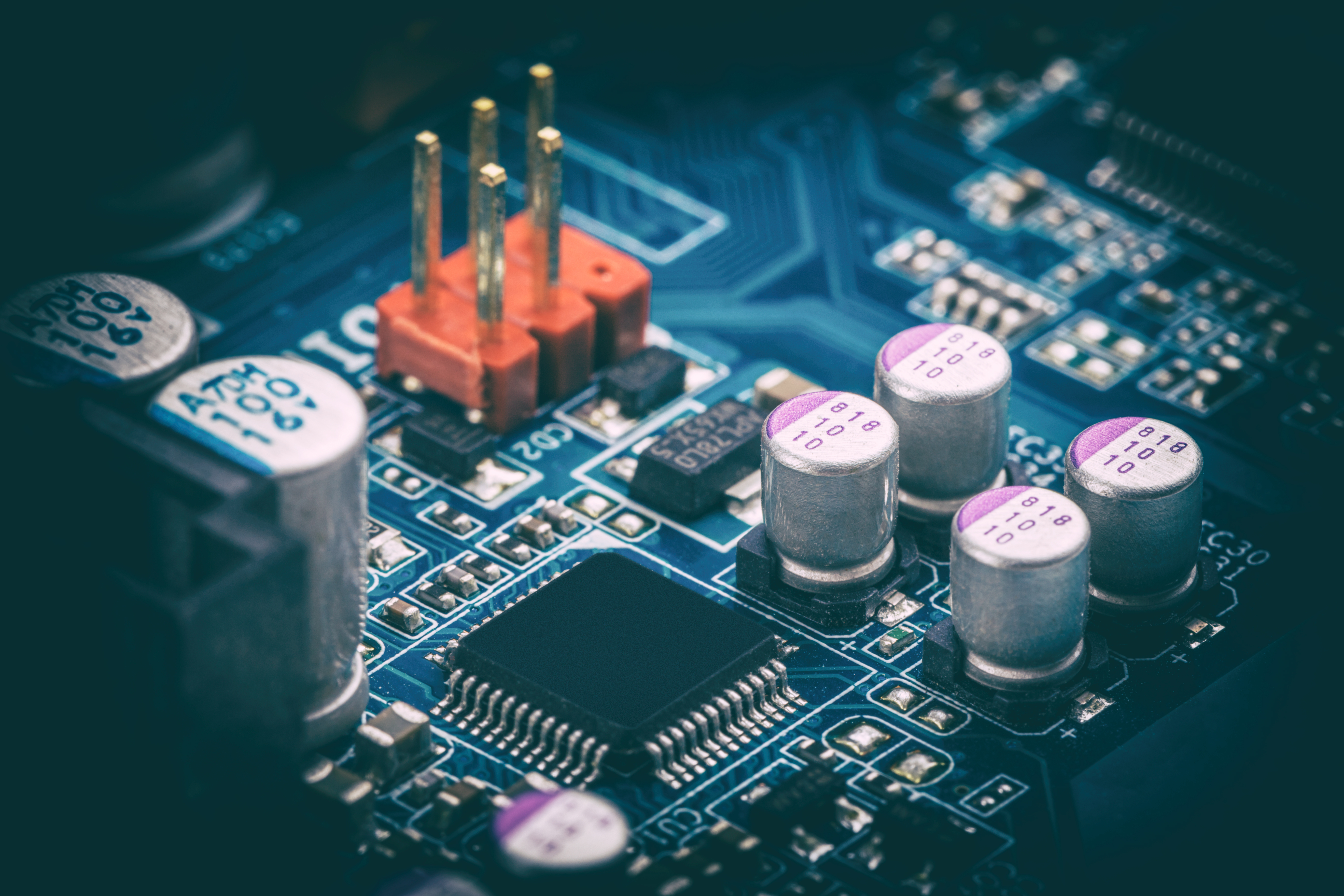

From wafer handling to chip manufacturing, lubrication isn’t an option. iNTECH’s PowerCore polymer exhibits unique properties, no particulate contamination, does not out-gas, self-lubricity, light weight and resistance to deformation, that maximize uptime in critical, demanding environments.

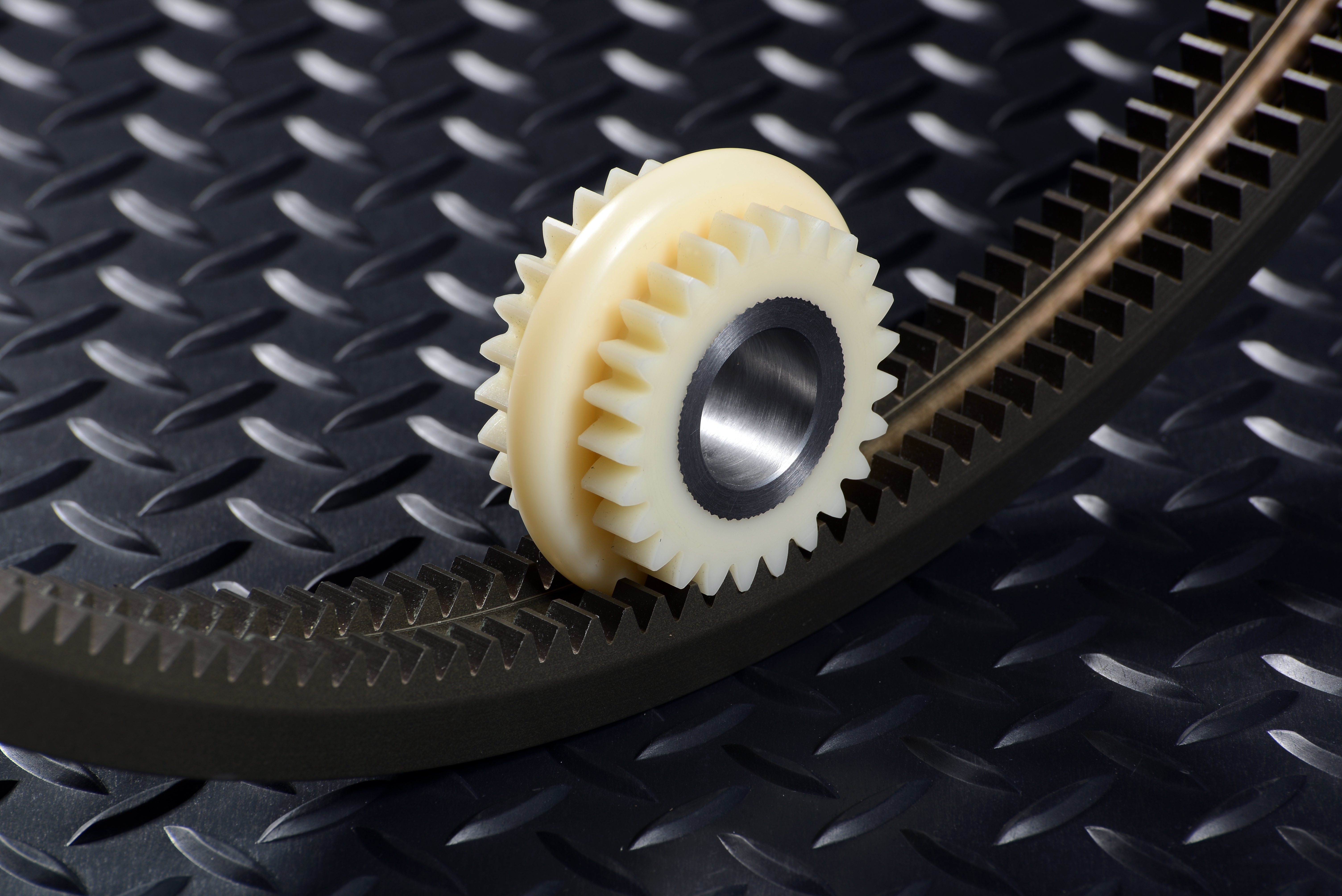

Our precision-machined, self-lubricating track rollers and AGMA 10+ gears are the trusted choice for cleanrooms and vacuum conditions — perfect for semiconductor manufacturing.

Thanks to their self-lubricating, lightweight nature, our polymer components avoid the traditional pitfalls of their common plastic or traditional metal counterparts.

Metal particulates, outgassing and other contaminants released by greases and metal-on-metal wear aren’t acceptable in the vacuum environments common to semiconductor manufacturing. Rely on our PowerCore gears and guide rollers (with optional ceramic bearings) and never lose a batch again.

Semiconductor manufacturing needs to be consistent and smooth in order to avoid defective batches and excess wear. That’s why our engineers have developed several tooth mesh modifications for reducing or eliminating backlash that capitalize on the PowerCore polymer’s elastic properties.