250 Herbert Avenue

Closter, New Jersey 07624 U.S.A.

1-877-218-2650

When it comes to life science and laboratory instruments, your choice of motion components can make a big difference in terms of performance. As a testament to this fact, a biotechnology company that specializes in detection and imaging equipment outfitted one of its automated liquid handling systems with Intech polymer guide rollers. Compared to previous motion components, these guide rollers have unlocked a number of benefits, including long, wear-free service life, which has helped improve the speed and performance of the dispensing system.

The biotechnology company’s liquid handling system is ideal for applications that involve sample preparation. It features a gantry-type dispense arm, as well as tools that accommodate solid phase extraction and magnetic bead separation. Thanks to this flexible workstation, users can extract and purify genomic DNA, RNA and Plasmid DNA, as well as polymerase chain reaction (PCR) and sequencing setup and cleanup. Users can also configure their workstations based on different variables, including the size of the instrument, pipetting arm technology and labware movement.

Other benefits of the workstation include:

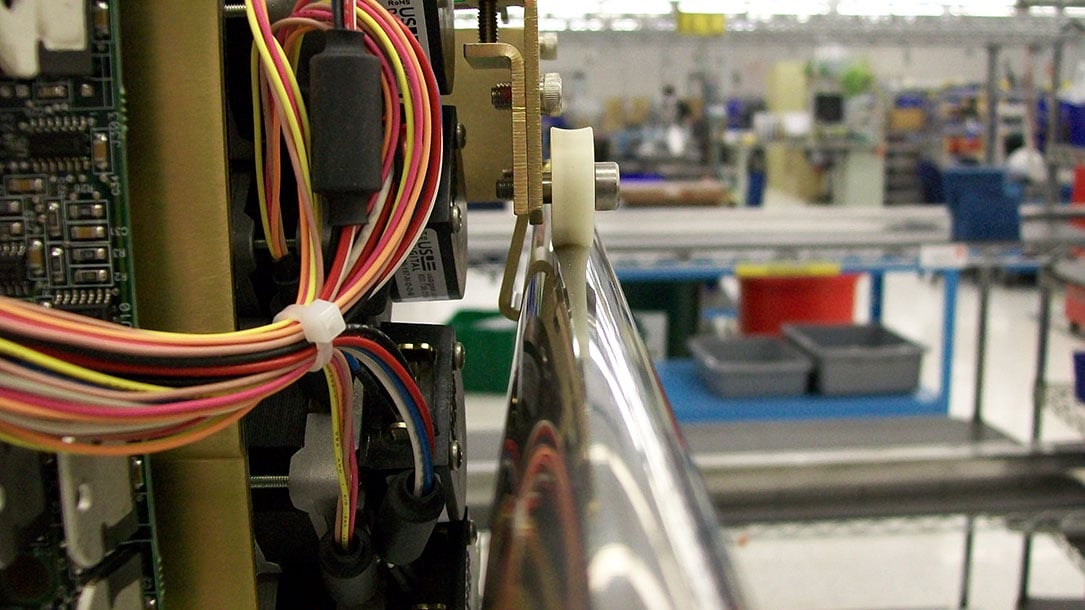

A key component of the workstation is its integrated Cartesian robotic system. This robot provides motion in the X, Y and Z axes and must maintain high accuracy and repeatability over many move cycles. To help them achieve these goals, the company’s design engineers selected Intech guide rollers. Made from our proprietary Power-Core™ polymer material, these guide rollers are a critical part of the motion system, which enables researchers to use the workstation to test thousands of samples in a fraction of the time it takes lab technicians to test only a few.

Self-lubricating and wear-free design. The Intech guide roller, which supports the front of the robotic arm, rides on a stainless steel rail that is external to the system. It provides a very smooth rolling surface without any lubrication, which is necessary for clean environments. The guide roller also avoids compression set and has been tested to show no signs of wear—even after extended life cycles.

Zero flat development. Plastic materials have the tendency to develop flat spots when they are at a standstill under static loads. A flat spot usually means the end of the guide roller’s life. In contrast, Intech’s engineered polymer, which the guide rollers are made from, features a highly crystalline structure, enabling it to withstand high loads. For this reason, our guide rollers and cam followers can sustain high static loads over prolonged periods of time without developing permanent flat spots.

Stability under varying conditions. Ideal for the biotechnology workstation, Intech guide rollers are precision-machined, enabling the robotic arm to move with precision. The Power-Core composite material also maintains its dimensions under varying conditions, which is a critical feature for the accuracy and repeatability of the operation. In addition, the material does not absorb moisture, is stress-free and retains elasticity over its entire temperature range: -40° to over +160°F.

Compared to our Power-Core guide rollers, the components the biotechnology company originally selected to support the front of the robotic arm were made from a softer compound that did not offer the reliability required by the instrument. Although switching over to our guide roller was a small design change, it improved the speed and performance of the motion system.

By selecting a guide roller with a long service life and lubrication-free operation, the workstation can now continue to fulfill the needs of the scientific and research communities.

To learn more about Intech guide rollers and our Power-Core material, please visit our product page.