250 Herbert Avenue

Closter, New Jersey 07624 U.S.A.

1-877-218-2650

When the design calls for a large bearing—for example, to support a large outer diameter (OD) ring gear—choosing a sturdy yet lightweight mechanism with the properties and stability for reliable performance can be tough. Finding an appropriate bearing that can operate in cleanroom, food processing or vacuum environments, with all their hygienic requirements, can be an even greater challenge.

The list of bearing considerations is lengthy. It includes accuracy and rotational tolerances, load handling capabilities, maintenance and cost—just to name just a few. One factor that’s central to all of these considerations is the construction of the bearing and its constituent components. Not only must the bearing support accurate, efficient motion, but it has to satisfy the need for lighter designs, which has been a constant trend across many industries and applications. And if the bearing’s intended environment is a vacuum, it can’t disperse any contaminants. At the same time, lubrication isn’t an option, making your material selection critical.

Unique Design and Materials Excel in Special-Duty Applications

At Intech, we have expertise in designing and manufacturing self-lubricating, lightweight machine components that can operate in difficult conditions. Drawing on decades of experience with designing gears, guide rollers and cam followers using polymer materials, we recently developed a versatile, large gear-bearing unit that is well-suited for hygienic or difficult environments, as well as for other applications where precise rotary motion and lightweight designs are essential. This bearing features a novel design that combines two components into one unit: a large aluminum ring gear driven by a pinion and supported by several, individually mounted guide rollers. The large ring gear is typically made from aluminum, and the pinion and supporting guide rollers are made from our Power-Core™ polyamide-based thermoplastic material. When the unit has to operate in vacuum, the gear is made from stainless steel.

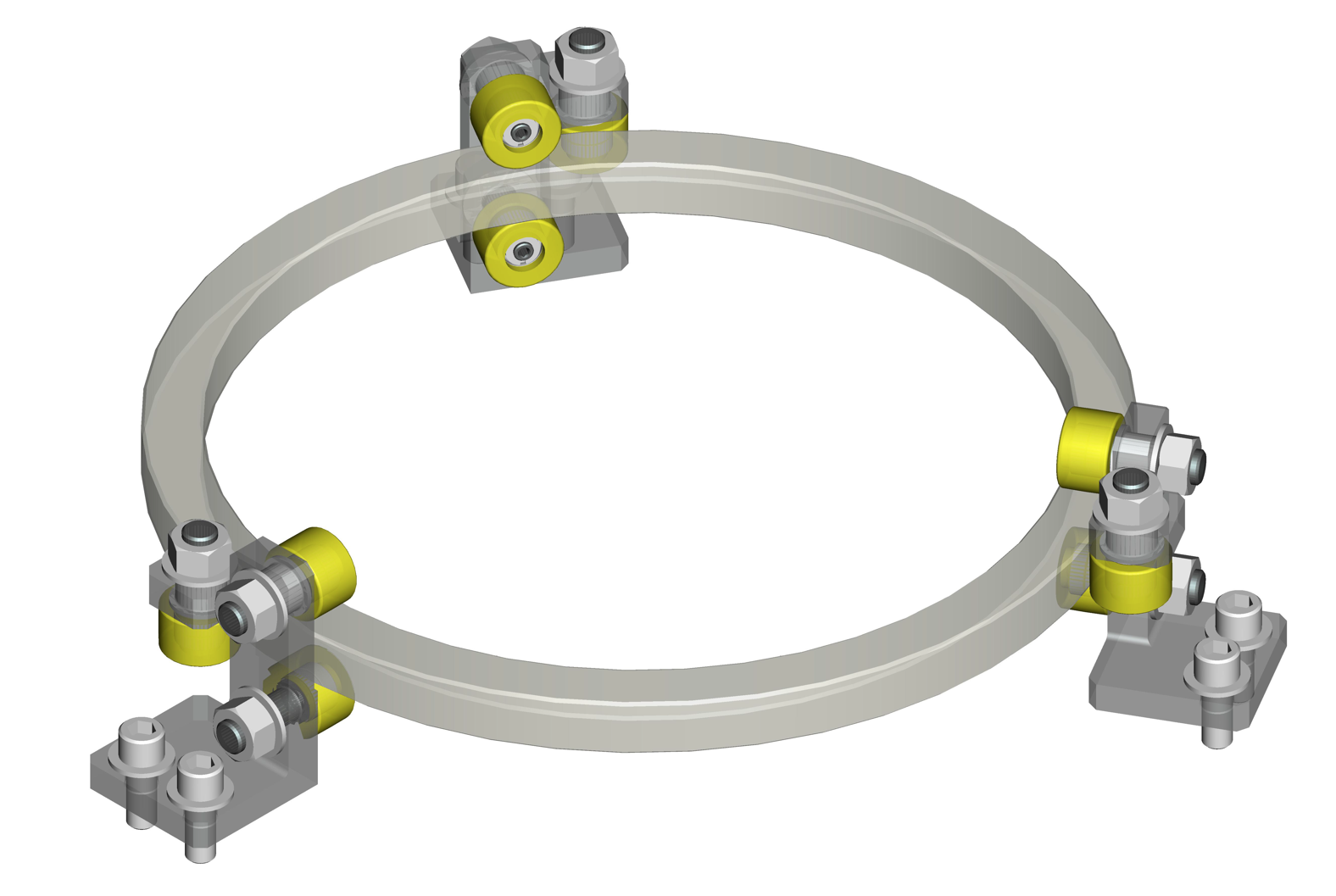

The large ring may have an internal gear, or the teeth can be machined outside the ring, and the drive gear is a Power-Core pinion with integral metal core. Spaced around the perimeter of the ring gear are the supporting cam followers that both locate the gear in place, axially and radially, and enable the rotating motion. (Picture 1) By using an engineered polymer as the bearing surface, these cam followers can withstand large forces, have a long wear-life and offer many additional advantages.

Picture 1: Design principle of an iCam® support of a rotating gear ring with internal gear teeth.

Hybrid Construction Provides Many Advantages

The Power-Core engineered polymer offers several advantages versus other materials. It can handle high mechanical loads that are prohibitive to other plastics, and it even exhibits higher strength than similar injection-molded polymers. In fact, some of the larger structural parts we’ve designed have been able to withstand continuous forces of several metric tons. Despite our advanced polymer’s high strength, it’s also very lightweight.

When the unit’s weight and inertia is a concern, the ring gear is made from aluminum. Together in this unique design, the aluminum and polymer materials create a lighter gear/bearing unit and deliver a host of benefits for many applications:

In addition, our Power-Core large gear-bearing design is especially suited for harsh environments, including vacuum conditions and environments subject to washdown.

Optimize Components to Fulfill Your Needs

If you need a large bearing that must meet strict requirements, achieve a long operating life or run without lubrication, chances are a large metal bearing isn't an option. And if you’ve never worked with an integrated-type bearing or one that’s made with our Power-Core material, you likely have questions.

We’re ready to assist you with designing your large diameter gear-bearing and can help you make predictable life-cycle calculations on both plastic or metal components. Our gear life calculator, for instance, uses an algorithm specific to Power-Core gears that lets you estimate the number of hours the gear will last in your application, based on torque, RPM, shock load and other operating parameters. The design of our cam followers and guide rollers is based on similar calculations.

For more information about our Power-Core large diameter integrated gear-bearing technology, or to get started with our wear life calculation, contact an engineer.