250 Herbert Avenue

Closter, New Jersey 07624 U.S.A.

1-877-218-2650

If you’re designing for packaging or processing machines in the food and beverage, pharmaceutical or electronics industries, then you might want to reach for cam followers that can endure frequent washdown cycles, resist contamination and corrosion and exhibit long wear life. At Intech, we offer several high-performance, greaseless iCam® Follower options for these environments. These options include:

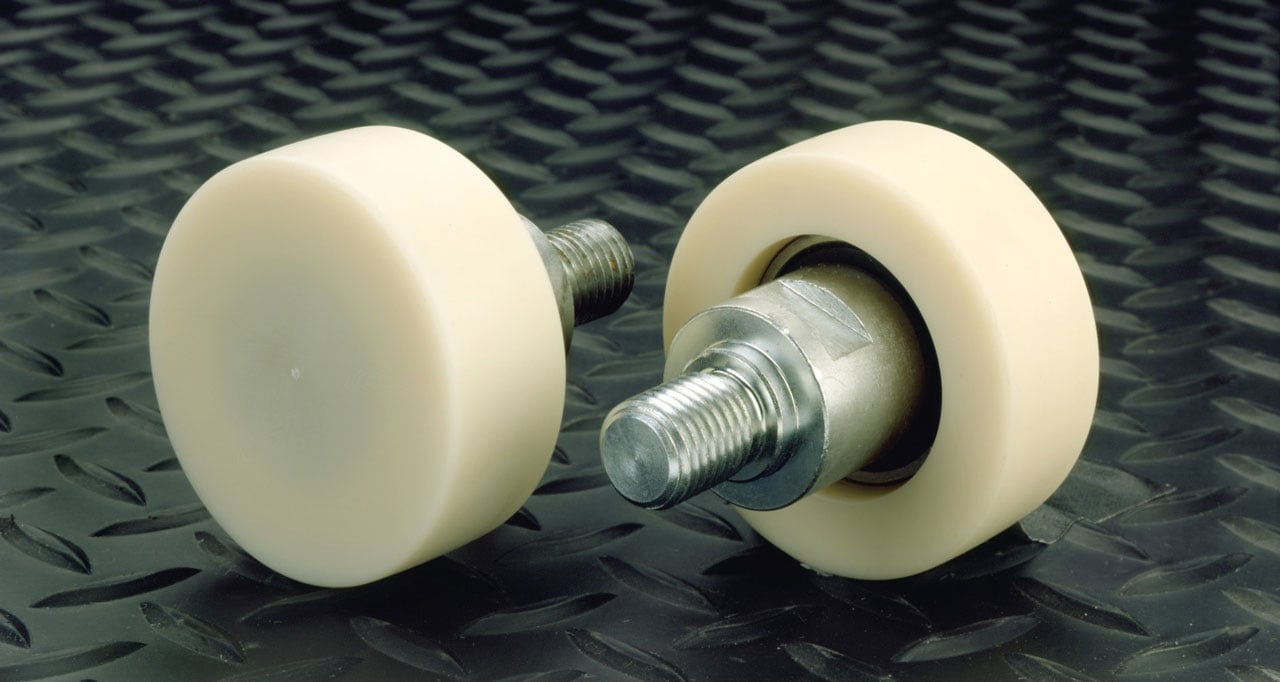

2.25" capped Intech iCam® Followers with a custom shaft.

2.25" capped Intech iCam® Followers with a custom shaft.

Our iCam® Followers feature sealed bearings, as well as a self-lubricating, wear-resistant bearing surface — made from our Power-Core™ polymer material — that eliminates two potential sources of contamination often caused by metal cam followers: stray lubricant and particulates from metal-on-metal wear. In addition, the material does not absorb moisture, is resistant to aggressive chemicals and does not outgas in a vacuum. For these reasons, our iCam® Followers are a good choice for medical, semiconductor, food processing, liquid filling and cleanroom applications. And, our iCam® Followers have the added benefit of eliminating the time it takes to regrease moving components after washdown cycles.

Our cam followers are also available with an end-cap design. One side of the plastic roller is enclosed, or capped, protecting the precision ball bearings that are fitted into the polymer tire from contamination and high-pressure washdown solutions. If required, we can even seal the shaft; for example, a pharmaceutical company that wanted to guard against any potential grease leak from the bearings opted for this design. The cam followers with sealed end caps are also available with an eccentric shaft.

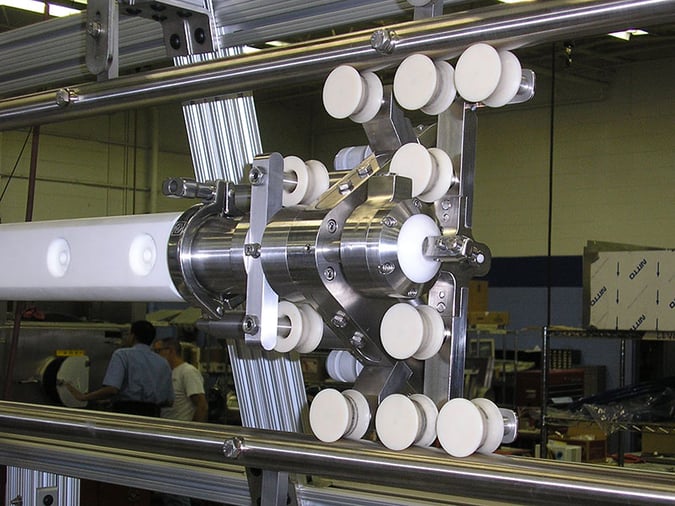

Concave, capped iCam® Followers on a pharmaceutical processing machine.

Concave, capped iCam® Followers on a pharmaceutical processing machine.

Our iCam® Followers with sealed stainless steel bearings and shafts are a go-to choice whenever corrosion is likely. But you also have ceramic ball bearing options, which many customers who use more aggressive washdown solutions prefer. It’s worth noting, ceramic bearings do have a limited load capacity. However, if load isn’t an issue in your application, then these bearings will get the job done — and you don’t even need to enclose them.

In addition, ceramic bearings reduce friction and don’t rust, which is especially appealing for hygienic environments. You can choose either all-ceramic bearings or hybrid ceramic bearings, which combine ceramic ball bearings with a steel race to withstand some shock load. Our all-ceramic and hybrid ceramic ball bearings are available with or without lubrication and are sealed with Teflon®. Due to their ability to resist aggressive washdown cycles, these models are currently gaining popularity in many food and beverage applications, such as dairy plants.

Our iCam® Followers with sealed bearings and end-cap designs, as well as our ceramic options, are available in both inch and metric units. And, whether you select a cam follower with stainless steel, ceramic or hybrid ceramic ball bearings, our self-lubricating, polymer load-bearing surface extends your maintenance intervals, keeping your uptime high and reducing your overall costs.

iCam® Followers with end-cap design. The shape of the polymer outer racer can be designed to suit your application.

iCam® Followers with end-cap design. The shape of the polymer outer racer can be designed to suit your application.

To learn more about your cam follower options for corrosive and contamination-sensitive environments, please contact our engineering team. Give us a call for a free consultation to explore how our iCam® Followers can benefit your application.