Large Plastic Parts for Electrically Insulated Robotic Arm

INTECH Power-Core™ electrically insulated robotic arm is designed as a load carrying structural element with no reinforcement. In addition to the robotic arm other parts such as axis 4, 5 and 6, elbow valve manifold and bearing retainers were also designed using Intech Power-Core™. These parts' design and their structural integrity was optimized in a joint effort between Intech's and our customer's engineers using exhaustive stress analysis.

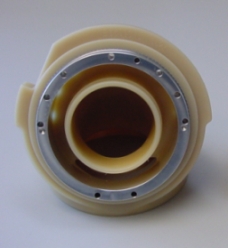

The complex parts are gravity cast into molds and then placed into an oven, where a temperature controlled process results in polymerisation and later homogenous crystallisation of the plastic material. Subsequently any functional surfaces, such as bearing seats, are precision machined. Since the Power-Core material does not swell in moisture, the cast components retain the tight tolerances required for assembly and reliable function of the robotic arm.

Auto Paint Spraying Application:

Electrically insulated robotic arms are used for painting autos. During the spraying process a 100,000 volt electrical charge is applied to the paint, and an opposing charge is placed on the surface of the auto being painted. Traditionally auto painting robotic arms are made of aluminum. Voltage fluctuations cause some paint returns to the conductive aluminum robotic arm, causing substantial losses in expensive paint. To facilitate cleaning, the aluminum arms are covered with special blankets, which are disposed of daily.

Requirements:

To ensure reliable bearing seat in high stress areas of the axis components, Intech cast in an aluminum ring (see image below). Intech's customer registered several patents on the electrically insulated robotic arm and was able to introduce safe, environmentally friendly water based paint.

Benefits of INTECH Power-Core material:

Benefits of INTECH Power-Core material:

- Reduced weight increases mobility

- Extended life compared to aluminum parts

- Lower energy costs

- Paint wastage and clean up minimized