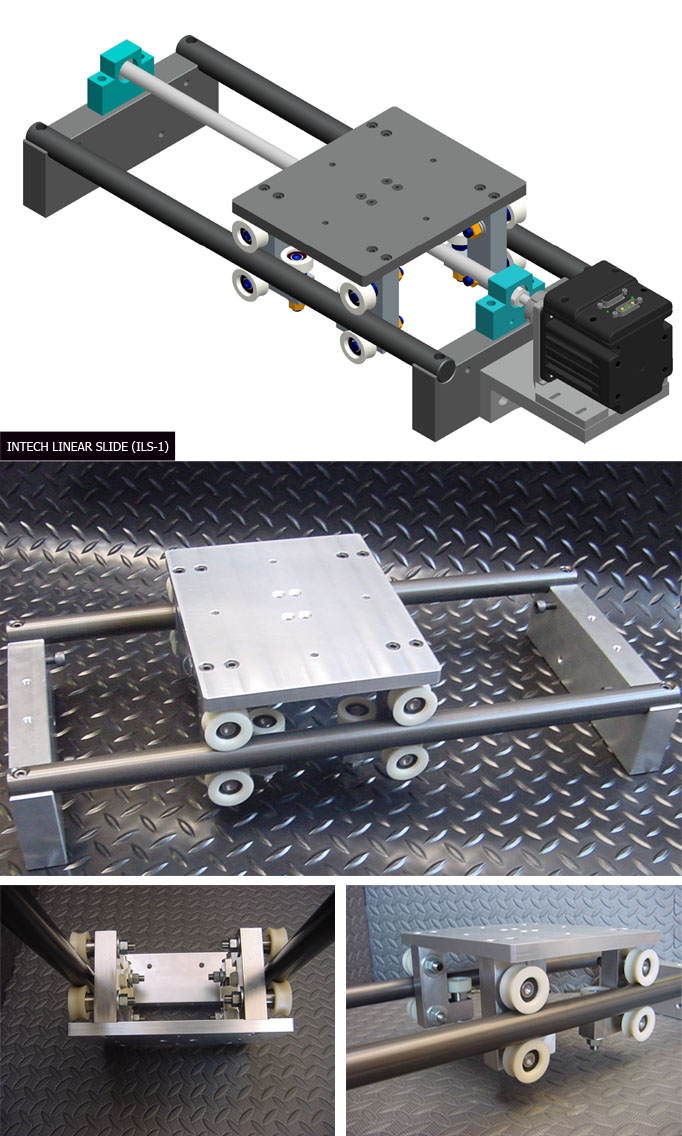

Intech Linear Slides

A stable linear motion platform with low rolling resistance, long wear life, and requiring no lubrication. In many applications we are asked to create a solution that will operate in a sanitized environment, so our linear slides are designed for easy cleaning access and to withstand frequent washdowns.

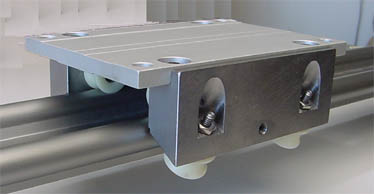

Trolley Design Configurations

- Several lubrication free concave Intech Power-Core™ rollers

- A third flat guide roller takes the side load and guides the linear motion of the platform

- Platform is mounted on four brackets smoothly along the rail with two parallel round shafts

- The Intech Power-Core™ rollers use stainless steel ball bearings with less rolling resistance

Linear Slide with Intech Roller Assembly

Features

- Self-lubricating operation

- “Backlash free” movement – thanks to the three rollers mounted on each of the brackets

- Two concave rollers, one eccentric , are used to secure the assembly in the vertical plane and an additional flat roller, also with an eccentric shaft, takes any horizontal load

- Adjustable - Two flats on the stand off part of the shaft shafts, between the roller and the bracket, allow application of a flat wrench while adjusting the eccentric rollers on the shaft

- Designed for easy cleaning access

- Easy assembly - The same bracket can be used in either the left or right position, which means the platform size is adjustable according to the application needs

- Can support platforms, weighing around 300 lbs

- Platforms may be driven by belt drive

Applications

Intech Power-Core™ rollers and gears reduce contamination, since they are non-lubricated, and this makes them ideal components in Filling-Sealing-Packing Machines for food, dairy, cosmetics, beverage, and the water industry.